1982 Yamaha Vision (XZ550) Fuel Injection Conversion

This is what I want my Vision to look like.

The photo above is what I want my bike to look like, but I have a lot of work to get it there. I snagged this pic from riders of vision because mine is currently disassembled.

Yes, this is a lot of effort for minimal return, but I find it interesting. I bought a very used Vision in the fall of 2003 for somewhere between $100 and $200. It ran on starter fluid or sprayed gasoline, but not on its own. I bought the Haynes manual, 5 bottles of carburetor cleaner, and I tried my hand at cleaning the carburetor. It turns out that I am not a master carburetor cleaner. After two dis-assemblies and cleanings, the best I could manage was a putter or two while trying to start. The local Yamaha dealer wanted almost $400 to rebuild the carbs, which would have been the easy way out until they needed cleaning again. The other great thing about this rare bike is the total lack of carburetor rebuild kits. In retrospect, there were probably some vacuum seal problems in the dry-rotting rubber intake manifolds and in the YICS chamber and tubing.

I like carburetors when they work, but I find them technologically inferior when they do not. I had my eye on some newer bikes with fuel injection for a while. I also had a desire to learn to use microcontrollers for work-related projects. Then I realized that the obvious solution was to build my own fuel injection system.

I researched electronic fuel injection (EFI), pulse width modulation, microcontrollers, fuel injectors, fuel pumps, and carburetors. I came up with a rough implementation plan and bounced it off a few of my engineer coworkers. Their initial reaction was "why bother?" and they bet that it would never work. After further discussions, they bet that it might work, but it would not beat the gas mileage of a Dodge Durango 5.9L V8; about 15 MPG. The challenge was on.

Here are some great Yamaha Vision XZ550 websites:

Wikipedia's Yamaha XZ 550 Page

XZ550.com

Riders of Vision

JetAV8R's Vision Page

Air and Fuel Consumption Near Standard Temperature and Pressure

| Air Volume Per Intake Stroke (cc) | 275

|

|---|

| Air Density (g/cc) | 0.0012

|

|---|

| Air Mass Per Intake Stroke (g) | 0.33

|

|---|

| Air Fuel Ratio | 14.7

|

|---|

| Fuel Mass Per Intake Stroke (g) | 0.02245

|

|---|

| Intake Strokes Per Revolution | 1

|

|---|

Here are some initial calculations that prove it is quite possible to beat the Durango. The Vision's 4-stroke V-twin spins at 5300 RPM at 60 mph in 5th gear. The ideal wide-open throttle (WOT) fuel consumption is 0.02245 g/intake stroke near sea level and 32 degrees F with a perfect intake system. The WOT fuel consumption rate is then 118.985 g/minute or 7139.1 g/hour. Gasoline is approximately 0.73722 g/cc, so the rate is 5263.09 cc/hour. One gallon is 3785.41 cc, so the rate is 1.39 gal/hour. The fuel consumption at WOT for 60 miles at 60 MPH is 1.39 gallons or about 43 MPG. Usually WOT will not be required to maintain 60 MPH, so actual fuel consumption should be less than 1.39 gal/hour and actual mileage should be more than 43 MPG, but this establishes a useful baseline for comparison.

Injector Sizing

| Maximum RPM | 10000

|

|---|

| Fuel Mass Per Intake Stroke (g) | 0.02245

|

|---|

| Maximum Fuel Consumption (g/hour) | 13470

|

|---|

| Maximum Fuel Consumption (lb/hour) | 29.634

|

|---|

| Cylinders | 2

|

|---|

| Maximum Fuel Consumption Per Cylinder (lb/hour) | 14.817

|

|---|

| Maximum Fuel Consumption Per Cylinder (cc/minute) | 152

|

|---|

The EFI system will use one MSD 12V saturated circuit 19 lb/hr injector (PN 2016) for each cylinder in a dual throttle body injection (TBI) layout.

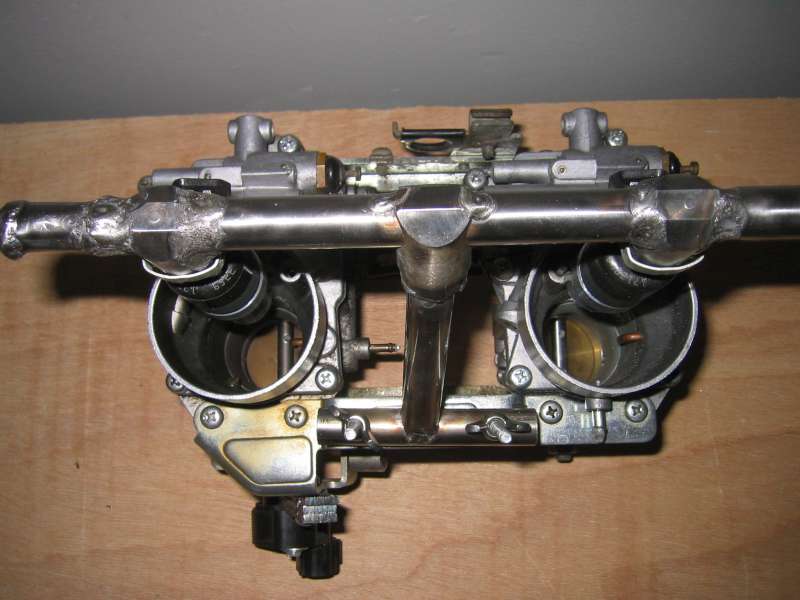

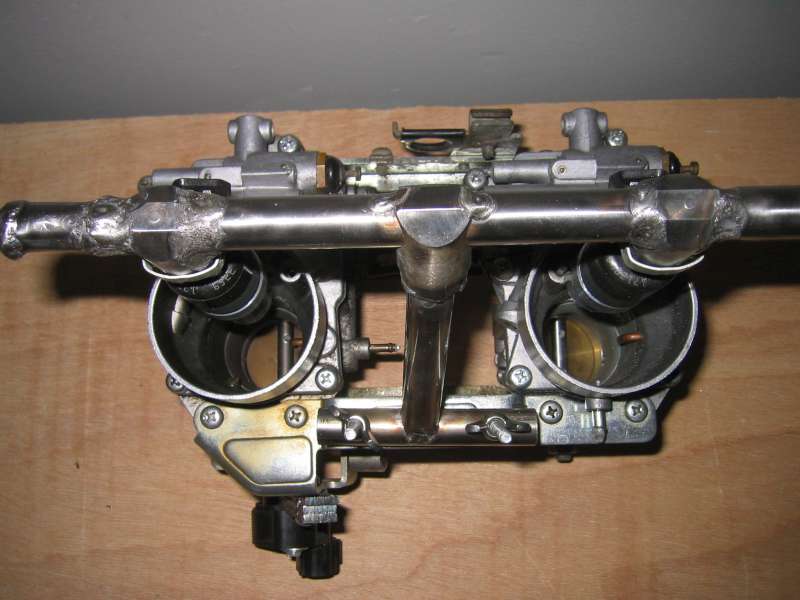

Dual TBI Right Side View

This is the complete dual TBI based on the original Mikuni carburetors. The stainless steel fuel rail is built from MSD components and was my first shot at TIG welding stainless steel. It is not pretty but it is air tight. The anodized aluminum hose barb was J-B Welded to the fuel rail. All of the unused carburetor fuel and vacuum passages were J-B Welded closed. The throttle position sensor (TPS) on the lower left of the image is from a 1999 Jeep Wrangler 4.0 I6. The injectors are almost perfectly in line with the airflow through the carburetors. The custom air cleaner will come last and I will test without one.

Dual TBI Overhead View

The TPS is actuated by a flat bar that I welded to the rear throttle plate shaft.

TPS Interface

The dual TBI system fits great. The positioning of the TPS was absolutely critical, which ended up with less than 1/8 inch clearance.

Dual TBI in Bike Right View

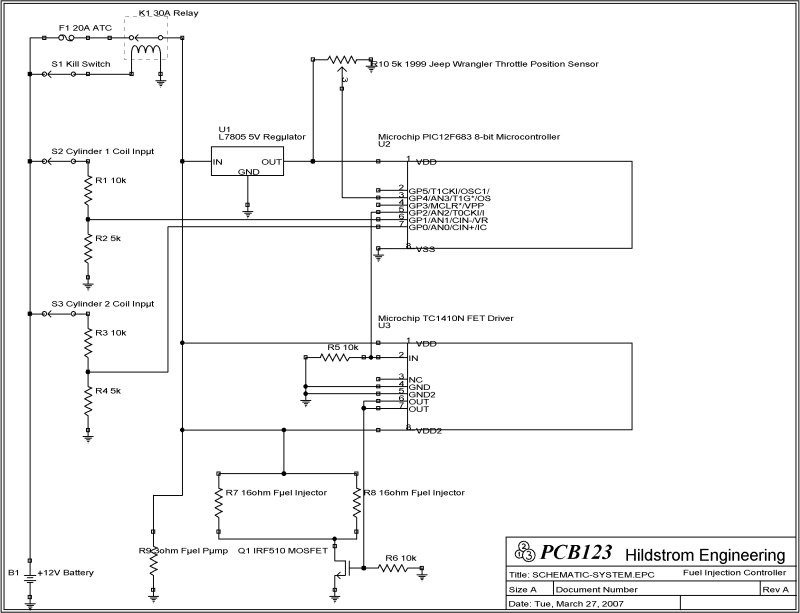

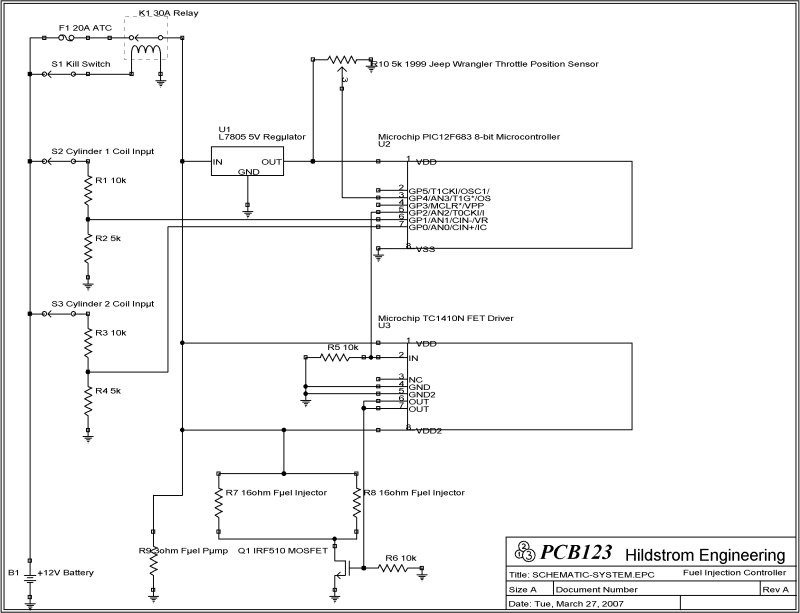

The fuel injection controller will utilize a Microchip PIC12F683 microcontroller as the system computer. I created the schematic with PCB123, which is a great program.

System Schematic

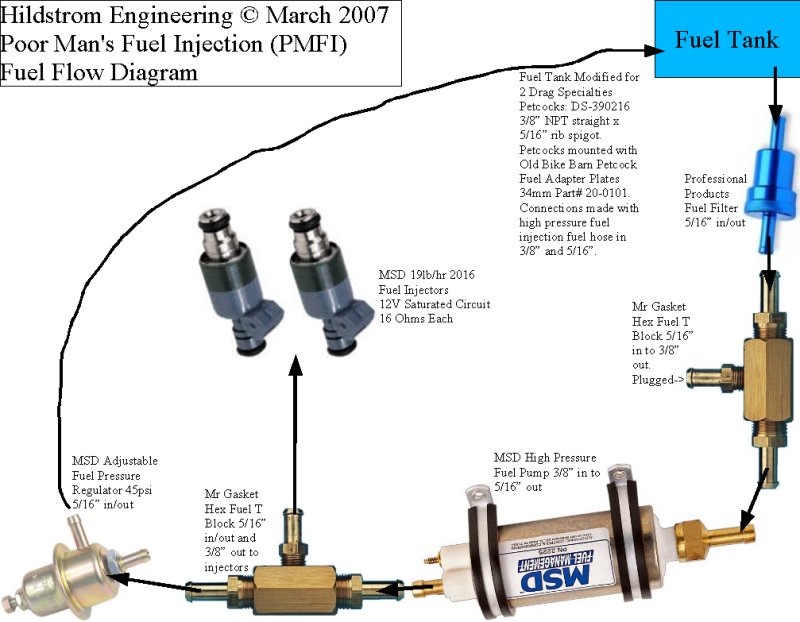

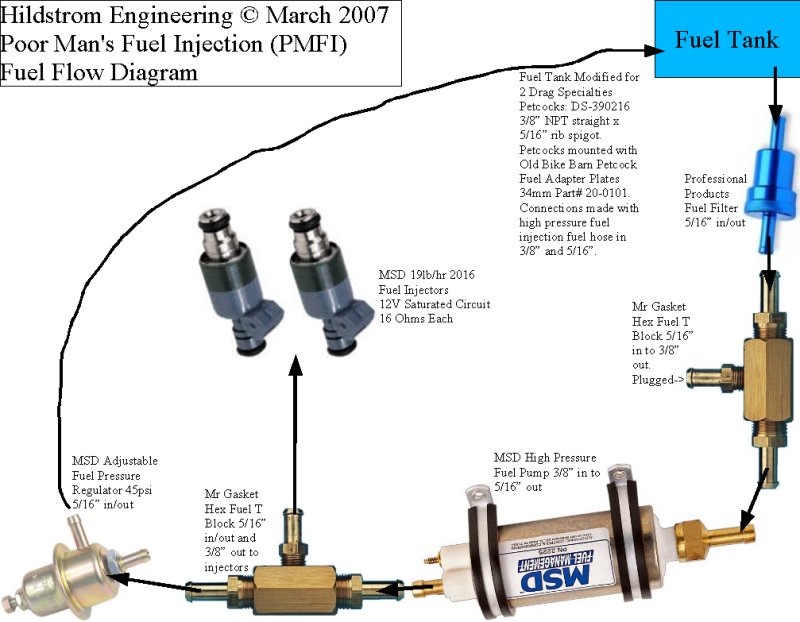

The fuel system, like almost all electronic fuel injection systems, must continuously pump fluid in a loop.

Fuel System Diagram

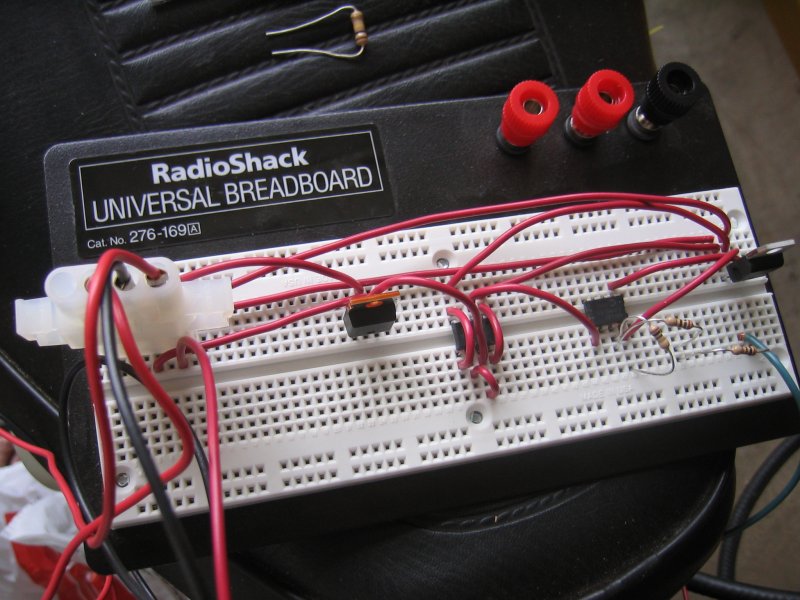

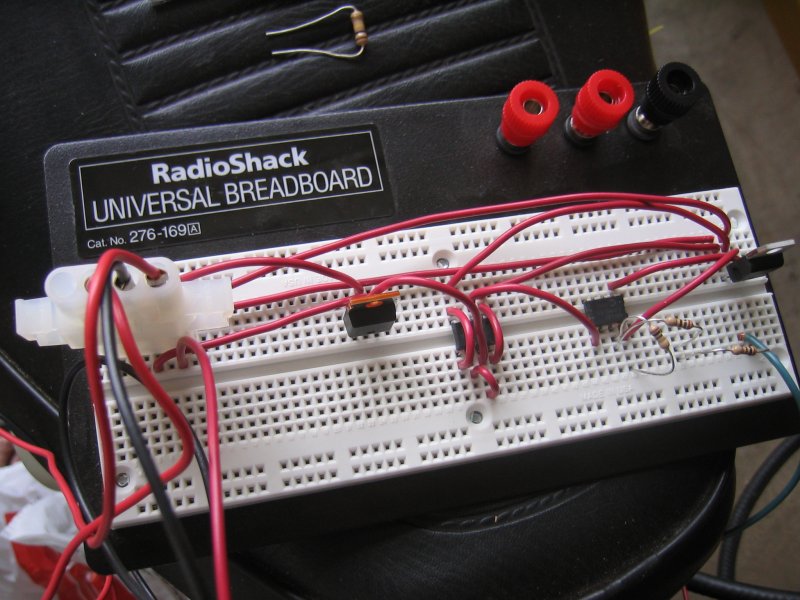

Here is the prototype fuel injector controller.

I managed to get the bike to putter for a few seconds on fuel injection before it backfired out the throttle bodies into my right ear. I heard ringing in my right ear for 24 hours or so. The vision definitely has the wrong ignition system to be developing any type of fuel system with. It tends to spark one last time when cutting out, so this last random spark may occur when an intake valve is still open. I declared success as far as learning a thing or two about microcontrollers and fuel systems, but decided that I needed to dedicate my time to other endeavors. I bought a used set of carbs on ebay that came off a running 1982 vision. I put them on the bike and gave it away on Craigslist. Hopefully someone else will have fun with it.