|

Projects Publications Resume Contact About Youtube |

|

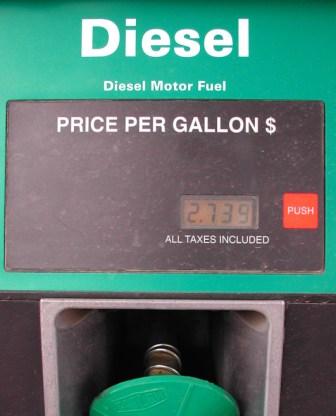

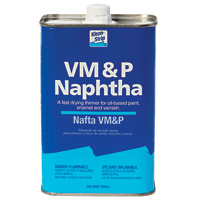

| 4 parts Diesel | 2 parts naphtha | 1 part IPA |

|  |  |

| msds component | purpose | msds mass % | homebrew component | source | component cost $/oz | density g/ml | volume | mass | mass ratio | solution cost $/oz | solution cost $/pint |

| pale oil | lubrication | 40-60 | diesel | fuel station | 0.0215 | 0.85 | 4 | 3.40 | 0.60 | 0.0123 | 0.20 |

| naphtha | cleaning | 25-35 | naphtha | Klean Strip, Home Depot | 0.2100 | 0.75 | 2 | 1.50 | 0.26 | 0.0600 | 0.96 |

| IPA | drying | 10-20 | isopropyl alcohol 91% | pharmacy | 0.0900 | 0.81 | 1 | 0.81 | 0.14 | 0.0129 | 0.21 |

| total | 7 | 5.71 | 1.00 | 0.0851 | 1.36 |

| 2 parts Diesel - 1 part gasoline |

|