Buell 1125R Heat Relief

The commute to and from my last house had many long stop lights, which led me to experiment with automatically disconnecting the rear fuel injector when in neutral for some heat relief. That helped while sitting at traffic lights on 100+F days, but it did nothing to reduce heat transfer to the rider while riding. The aluminum frame/tank straddles the engine and the rear exhaust header. I made a video showing the gasoline in the frame/tank boiling a couple years ago, but a recent long ride left me with burned knees that eventually blistered, scabbed, and peeled. I was wearing Wrangler Premium Performance jeans, which are thicker than most jeans, but definitely not as thick and tough as proper riding pants.

I seriously considered selling the bike for something different, but eventually decided to try fixing it. With 10000 miles on the bike, I knew I was probably close to needing a valve lash adjustment anyway, so I tackled a bunch of stuff during a single engine rotation. I didn't do the by-the-book engine rotation procedure in the service manual, but I did something similar. I didn't disconnect the rear wheel, any drive components, or any foot pegs. I also didn't rotate the engine down. With the bike on the rear stand, I built an engine stand in place that uses the factory muffler bolt holes. After removing the rear shock and the entire rear brake system, I rotated the frame up. This position gives access to both valve covers and the rear header bolts. I thought this would be a better position for working on valve lash than rotating the engine down. I also thought it would be more stable and secure. Unfortunately, there was a mistake in the factory wiring loom. I had to cut and extend three wires at the left front of the engine to allow rotation. I used 1.5"x0.125" and 1"x0.125" angle to make the engine stand. I TIG welded it in place on the bike. Stick or MIG would also work fine, but I didn't want to worry about protecting things from sparks and spatter. As my friend Chris pointed out, this is way overkill. Wood would work fine for this amount of weight, but I already had the angle and I'm trying to improve my TIG skills.

I dropped my headers off at Cradin in Boerne, TX for Zirconia based ceramic coating. They were friendly and knowledgeable. They urged me to be careful re-installing, so I baked them for 3 hours at 500F. The finish seemed a bit harder and less matte afterward. I was a little disappointed with incomplete coverage, but I planned on painting them anyway.

I applied VHT Flameproof Black and Satin, which are ceramic-based high temperature DIY paints, on top of the Cradin Zirconia ceramic. I followed the stepped curing procedure in my oven and really stunk up the house for a few hours. The heat shield came out great, but I had some incomplete coverage of my own in a few places on the headers. I wrapped them with DEI "Titanium" grade header wrap. This should help minimize radiant heat transfer from the headers to the frame/tank. The ceramic has many benefits, but one is that it will help protect against corrosion under the header wrap. I was careful to not overlap too much and I stopped just past the O2 sensors. Re-installing the stock muffler was a bit of a pain. The seal rings needed some persuasion with a wood block and small hammer to get past the additional thickness of the ceramic and paint. I shaved the outside of the seal rings with a razor blade until I was able to get the muffler back on.

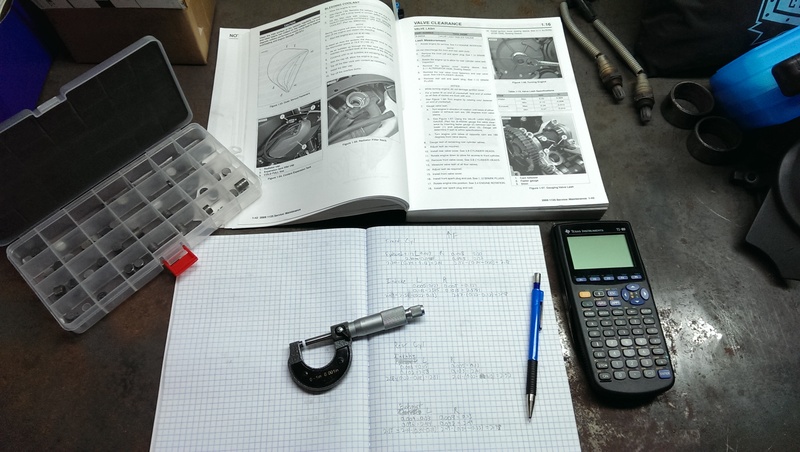

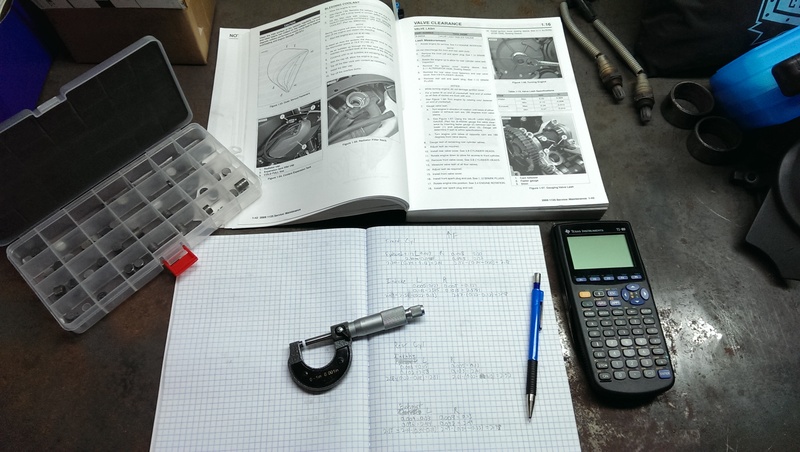

Since it was convenient, I adjusted all of my valves while everything was accessible with a Hot Cams 10mm Valve Shim Kit from Pro Cycle. All of my valves were out of spec too tight except for one, which was at the minimum. I adjusted them all near maximum. Doing this job with an inch feeler gauge and an inch micrometer is possible, but you'll have to spend a bit more time with paper and calculator than if you had the metric equivalents. Both spark plugs had eroded beyond the maximum gap, so I replaced them.

The original frame/tank insulation was peeling off the frame in several places. I guess it had seen too many hours at too high of a temperature for the adhesive to hold up. I removed it and wiped the frame/tank down with acetone and then denatured alcohol to make sure the new adhesive had a nice clean surface to adhere to. I replaced it with Thermotec Aluminized Heat Barrier and I covered more of the frame/tank than stock. This should help minimize radiant heat transfer from the engine and headers to the frame/tank. It provides a small amount of insulation against convection and conduction from hot air around the engine and from the radiators.

I cleaned with acetone and denatured alcohol, then installed TechSpec Gripster Snake Skin 0.125" rubber pads on the outside knee area of the frame/tank. They should provide insulation, grip, and some cushion. This should help minimize heat transfer from the frame/tank to my knees.

I installed the Erik Buell Racing (EBR) Race Engine Control Module (ECM) for stock exhaust. It is marketed for a bit of a power increase, but I'm more interested in a slightly richer fuel mixture to help keep exhaust and operating temperatures down. I installed a K&N reusable air filter at the same time.

After I triple-checked all of my fasteners during reassembly and got everything buttoned back up, I went on a 90-minute ride to give the ECM some learning time. This was also a good long heat soak for all of the exhaust components. It was night time, but ambient temperatures were still in the low 90's. The frame/tank still got warm, but not nearly as hot as before. I didn't feel any heat discomfort on my knees, inner thighs, or crotch. I parked in the garage afterward, came back 10 minutes later, and to my surprise, I wasn't overwhelmed with gasoline fumes like I normally would be. It seemed like a definite improvement, but my next long daytime ride in 100+F was the real test. I did the Three Twisted Sisters ride again, the same 300-mile ride that burned me, and it was much better this time. There was no heat-related discomfort and no burns.